To comprehend what a paper (blueprints) to CAD blueprint conversion is you must first comprehend what CAD is. These 3 letters represent Computer Aided Design or Drafting. In the past about 10 or more years ago the main kind of technical drawing or blueprint drafting was made with several various instruments that would carry out jobs like measuring, creating arcs and circles, offsetting lines that are parallel and perpendicular, and creating any type of line you can picture. Nowadays we use CAD to manage all of this work due to the accuracy, precision, and general ease of design it allows.

In the past all of the designs whether architectural, mechanical, civil, or a number of other technical drawings would be drawn by hand on a set of blueprints or paper. These blueprints drafting involve all the required info to properly design the designated project, however nowadays the industry standard is CAD blueprint drafting. So simply put this means there is a great deal of blueprints that require to be upgraded, and this is where you get the phrase paper to CAD blueprint drafting conversion.

When a drafter gets a set of blueprints drafting to be transformed into a CAD file she or he will tackle designing the technical drawing like they generally would. An appropriate set of blueprints must consist of a top, front, left, right, back, and bottom view together with an orthographic view or simply put a 3D viewpoint illustration that offers the object depth and a sense of reality.

Sometimes all of these views are not used mainly because all the essential information can be discovered without among the views. Special notes are also part of the blueprints and provide information to the designer or draftsmen that can not be seen by just taking a look at the different views.

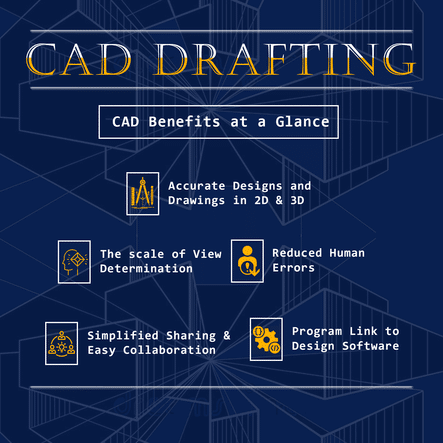

When working with CAD software applications, it will design the old boring 2D line and give them the 3D includes you need to totally understand the item. This software application is widely used by CNC makers where the information provided within the CAD drawing file will tell the CNC software how to design the part it’s working on. The capability to simply upload a file and have a mold-making maker develop a mold for production is very helpful.

A great advantage for CAD compared to a 2D Blueprint is that changes can be made at any time throughout the design process in case an error is made, or the design modifications from something like the designated tolerance, width of a housing, or size of a screw. When a Draftsmen deals with paper or blueprints they have to offer it a rub with a good old eraser to remedy any errors, and they still can’t go back and fix one view and have them all upgrade quickly.

There are a variety of reasons why blueprint drafting companies in Washington DC are tossing out the old blueprints and purchasing updated CAD files. Paper-to-CAD conversion will stay to be a part of the drafters’ tasks well into the future up until every design is lastly upgraded, and no paper blueprints remain.

The reality that a lot of production machinery collects its design details from CAD is another contributing factor to these paper-to-CAD conversions. If you would like to visit a company that produces paper to CAD converting please see the 3D CAD blueprint drafting company in Washington, DC.